A Simple Key For Domestic Decorating Dalton Unveiled

Do you really like home design and hope that one could turn your property-designing visions into lovely truth? Effectively, that you can do simply that. This post offers some great assistance, useful tips and awesome tricks to help you started. Make use of this assistance to assist you make spaces that one could be proud of.

In order to color the wall surfaces of your house however they are puzzled by what colour to use, piece of art diverse colour swatches on the surfaces will allow you to choose. Ensure that the swatches are large enough so as to evaluate with one another. In addition, be sure you permit the fresh paint dry before deciding so that you can evaluate the right color of the fresh paint.

Select your colours very carefully when you're taking a look at repainting a room. You want to opt for hues which are nicely collectively and match the other person. You don't want colours that clash and overcome for consideration. You need your hues to merge with each other and really feel organic. Don't opt for too many dazzling shades, or else you danger overwhelming your detects.

Prevent catering to any design styles which can be currently preferred. These tendencies tend to be high-priced, and they'll be away from style pretty quickly. Opt for something classic which you consider appears very good. Don't allow what current tendencies say are good affect the way you would like spot to seem. Stick to your center, not really a stylish magazine.

Ensure you have the storage space you want. You'll by no means get yourself a place seems like it arrived of any newspaper if there's mess just about everywhere. Seek out eye-catching containers protected in a cloth which matches the rest of the room. Once you make storage an integral part of your layout, it's simple to create a area appearance fantastic.

When redecorating a master bedroom, incorporating a little bit color might help. Paint one particular feature wall surface or include some extra strong pillows for the bed furniture. Location an accent couch in the area or use lampshades by using a bold burst of color. This brings graphic fascination for the area, and it is an affordable way to alter the place.

Try out holding your picture support frames at an eyes-levels, rather than increased up on a wall structure. Graphics hung too much allows the illusion of reduce ceilings. Retaining frames in a reduce level also ensures they are a lot more apparent, and keeps site visitors from being forced to lookup in order to view your stunning art work.

An incredible home design tip is always to start small. A number of people are scared of decor since they feel they must do it all simultaneously. You can actually start off very small, like choosing a light fixture or espresso dinner table that you really like. It is possible to them work after that.

Pedestal sinks are excellent options in little bath rooms. These sorts of kitchen sinks use up significantly less area, and so they come up with a modest toilet appearance greater. They likewise have a stylish interest them that is certainly traditional and works jointly with any decoration. You will find them at the local home improvement retailer at numerous value factors.

Use wallpaper to upgrade shelving. Put together-your self bookcases are an economical option, nevertheless they are generally uninteresting and search somewhat low-cost. So they are a lot more elegant, consider incorporating a striking wallpaper on the back of each rack. Prepare your guides and knickknacks to demonstrate the routine. This easy technique will give a shop-ordered rack some pizzazz without breaking the budget.

The entire lighting associated with a area depends upon the curtains you add up. More dark colours, like black, dark brown, and darker, red or glowing blue, do not allow enough sun light to get in your room, resulting in it to be darkish. Attempt to get lighter weight-tinted curtains, like suntan, white, peach, beige and taupe.

Be considerate of individuals that deal with you. You could possibly feel that you will be the most classy particular person you know, but bear in mind that other people will likely be inside the area frequently. Do your greatest to give up to ensure everybody is content with exactly what the ultimate look will likely be.

When your home does not have a good amount of sun light, you might like to look at painting your surfaces, notably should they be dim. Darkish shades have a tendency to take in light-weight whilst better and lighter in weight colors reflect them. Try piece of art your surfaces white Painting And Decorating Dalton colored to acquire more natural light in your home.

Try anything totally new. You may be thinking you do not like bright shades, for instance. You could possibly dislike velvet, but try it out anyway! What you believe you may not like may possibly in fact be merely the thing you will need in your home to make a new and different appearance. Start little, but striving new things allows you to re-evaluate everything you like and might do without.

Add more ceiling enthusiasts for your bedrooms. Exchanging normal lighting fixtures will ceiling supporters is a terrific way to add a attractive accent to your area and maintain the room more comfortable. Roof fans can be purchased in a variety of styles, and so they function in virtually any space. They are also cost-effective and simple to the do it yourself particular person to put in.

A fairly neutral skin cream is an excellent shade for the hallway. This colour is fairly neutral and may complement colours in adjacent spaces. It is also a light colour, and light-weight hues bring brightness towards the area and then make it seem larger. The hallway color will continue to operate even when you modify the shades of other spaces later.

If you intend to entertain a great deal within your living room area, be sure that you give adequate casual seats and desk room to your friends. Engaging generally incorporates providing food items. Delivering place for your personal company where by they may placed downward their cocktails and h'orderve dishes whilst they mingle together is likely to make points much more comfortable on their behalf.

If you wish to select an incredibly impressive desk that is going to be considered a focal point of your respective dining or living room, acquire one whoever thighs are typically taken away. This will likely turn your table into a more transportable item. You are able to bring it along with you whenever you shift, as well as up-date its appear later on by mounting it on new legs.

After reading the advice in this post, you need to know much more about how to get started with decor. It lacks as a hard exercise or one that you abandon to your specialist. With just a nudge in the appropriate course, you could start creating your home far more stunning immediately.

Desalination Plant Manufacturer Fundamentals Explained

Seawater Desalination with Reverse Osmosis Plant

All Reverse Osmosis crops are fundamentally Desalination Vegetation but desalination is becoming referred to sea drinking water Ordinarily.As sea water has really superior TDS demands really significant pressure to force sea water by means of membranes which happen to be various then brackish water membranes.

Reverse Osmosis Plant Information:

A reverse osmosis plant is often a producing plant, where by h2o is purified and desalinated by forcing h2o via a membrane, ordinarily known as a reverse osmosis procedure. Water made by plant RO may be used for several purposes like desalination, wastewater treatment, and also the reclamation of dissolved minerals.

RO Plant Description

An average ingesting drinking water RO plant technique calls for six KW hours of energy to desalinate a person cubic meter of drinking water. Reverse osmosis water crops necessitates a range of pre-treatment method strategies which includes softening, DE chlorination, and anti-scale treatment. Next pre-treatment method, large amounts of force deliver h2o by way of a semi-permeable membrane, which retains all contaminants other than water.

RO Plant Style and design

To boost the performance and life of the Reverse Osmosis plant, helpful pretreatment on the feed water is needed. Selection of the appropriate pretreatment will maximize effectiveness and membrane lifestyle by cutting down:

Fouling

Scaling

Membrane Degradation

RO plant style is consisting of:

Pinpointing pretreatment necessity of Reverse Osmosis Plant

If your feed water has traces of large metals, it is very suggested to dose some chlorine to change the dissolved major metals to physical kind, the media filter will filter a lot of it inside a ro drinking water purifier plant.

Reverse Osmosis Plant Array of membrane

Membrane components are a vital Element of RO plants. The proteins (mainly polyamide) that makeup membrane aspects change based on the ending clarity and intake water seawater or brackish water and so on

Waterman engineers Australia RO plant for seawater desalination

Waterman Engineers in Australia has made a Reverse Osmosis (RO) plant for seawater desalination, which presents quite a few advantages more than other desalination strategies. Here are a few crucial advantages of their RO plant:

Vitality Effectiveness:

When compared with other desalination approaches like thermal distillation, RO involves a lot less Electricity. Waterman Engineers' RO plant utilizes Superior membrane engineering, enabling it to operate at lower pressures and cut down Over-all Strength usage.

Environmental Impact:

RO generates fewer brine discharge when compared to thermal approaches, lowering the influence on marine ecosystems. This aligns with Desalination Plant Manufacturer Australia's concentrate on environmental sustainability and conservation.

Superior Drinking water Purity:

The RO process proficiently removes salts, minerals, and impurities, developing substantial-high quality freshwater that fulfills stringent drinking drinking water standards. This dependability is crucial for delivering Secure and cleanse h2o to communities.

Modular Design and style:

Waterman Engineers' RO plant employs a modular structure, enabling for scalability and adaptability. This is particularly advantageous for parts with different water needs, as modules is often included or adjusted accordingly.

Diminished Footprint:

RO crops generally Possess a scaled-down Actual physical footprint in comparison to thermal desalination plants, which regularly call for considerable infrastructure for heating and cooling procedures.

Quick Begin-Up and Shutdown:

RO vegetation might be commenced and stopped rather quickly, permitting for much better responsiveness to modifying water demands and emergencies.

Reduce Chemical Usage:

In contrast to Another desalination techniques, RO demands fewer chemicals for Procedure and cleaning, minimizing chemical-related environmental concerns.

Regularity in Effectiveness:

The RO course of action is considerably less sensitive to feedwater high quality fluctuations than other methods, making sure a more constant performance eventually.

Charge-Efficiency:

Whilst Original financial commitment fees can be sizeable, RO vegetation are likely to own reduce operational and servicing expenses Ultimately when compared with thermal techniques.

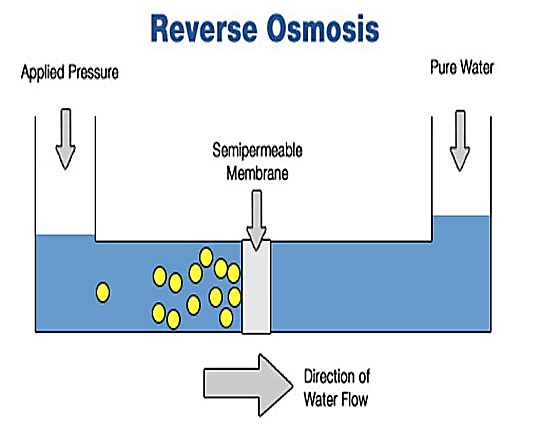

Reverse Osmosis (RO) is often a water purification approach that utilizes a partially permeable membrane to eliminate ions, unwanted molecules, and larger particles from consuming h2o. By applying force to beat osmotic pressure, it makes it possible for the passage of h2o molecules whilst rejecting contaminants, therefore developing clean water on just one facet of the membrane and concentrated impurities on another.

The Performing basic principle of the Reverse Osmosis (RO) plant entails applying strain to your saline Alternative to force water molecules through a semi-permeable membrane. This membrane enables only water to pass although rejecting salts, contaminants, and impurities, leading to purified drinking water about the permeate aspect and also a concentrated Alternative of contaminants on the brine facet.

Some great benefits of Reverse Osmosis include producing high-high quality, clean h2o by eradicating contaminants, remaining economical and price-powerful after a while, necessitating minimum chemical use, and becoming adaptable to numerous scales of Procedure from tiny house systems to significant municipal vegetation.

RO plants have changed Demineralisation (DM) vegetation since they often offer a a lot more effective and price-successful Answer for h2o purification. RO techniques don't have to have the regeneration chemical substances that resin-centered DM vegetation do and will get rid of a broader range of contaminants, which include dissolved solids and microorganisms.

Waterman Engineers Australia probably uses Reverse Osmosis (RO) vegetation for seawater desalination by forcing seawater via a semi-permeable membrane to remove salt together with other impurities. This process generates fresh, potable water with the ocean, addressing water scarcity and offering a sustainable source for numerous demands.

What Does Designing OF SHELL AND TUBE Heat Exchangers for Floating Liquefied Natural Gas (FLNG) Mean?

Floating Liquefied Natural Gas (FLNG) production, liquefaction, and storage facilities have revolutionized the extraction and processing of natural gas from remote offshore reserves. These offshore platforms offer unprecedented flexibility and efficiency in the production of liquefied natural gas at sea. Among the crucial components of FLNG systems, heat exchangers play a pivotal role in the liquefaction process. This article explores the intricacies of heat exchanger design for FLNG, focusing on the challenges and requirements unique to these cutting-edge offshore installations, with a special emphasis on Waterman Engineers Australia's expertise in this field.

Understanding the FLNG Process: FLNG facilities essentially function as floating liquefaction plants, enabling the extraction, liquefaction, and storage of natural gas at sea. The process involves several vital steps:

- Production: Natural gas is extracted from offshore wells using production platforms or subsea systems.

- Gas Treatment: To ensure the purity of the gas and prevent interference with the liquefaction process (e.g., from carbon dioxide, water, and sulfur compounds), the extracted gas undergoes treatment.

- Liquefaction: The processed gas is cooled to extremely low temperatures, typically below -160 degrees Celsius (-256 degrees Fahrenheit), causing it to condense into liquefied natural gas (LNG). This liquefaction is necessary for efficient storage and transportation.

- Storage and Transportation: The produced LNG is stored in onboard tanks before being loaded onto carriers for transportation to markets.

The Role of Heat Exchangers in FLNG: Heat exchangers are indispensable components of FLNG facilities, primarily responsible for managing the heat transfer required to chill natural gas to the liquefaction stage. This critical task involves handling extremely low temperatures and ensuring efficient heat exchange across various process streams. Key considerations in designing heat exchangers for FLNG include:

- Cryogenic Conditions: FLNG operations entail working at cryogenic temperatures, posing a significant challenge for heat exchanger design. Selecting appropriate materials, such as aluminum alloys and stainless steels, is crucial to withstand these harsh conditions. Insulation and thermal management strategies are also employed to prevent heat loss and maintain the required low temperatures.

- Optimizing Liquefaction Efficiency: Achieving economic viability hinges on maximizing the efficiency of the liquefaction process. Modern heat exchanger topologies like spiral-wound or plate fin heat exchangers offer improved efficiency by providing a large surface area for heat exchange in a compact design. Computational fluid dynamics (CFD) simulations are essential for optimizing heat exchanger components.

- Compact Design for Limited Space: Space constraints are common in offshore FLNG operations. Hence, compact heat exchanger designs like plate and frame or brazed plate heat exchangers are preferred, as they offer high surface area-to-volume ratios, enabling efficient heat exchange in a confined space.

- Durability in Harsh Marine Environments: FLNG heat exchangers are exposed to severe maritime conditions, including high winds, salinity, and potential wave action. Ensuring longevity requires the use of corrosion-resistant materials and coatings, along with robust monitoring and maintenance systems to detect and address corrosion issues.

- Operational Flexibility: FLNG operations can experience variations in gas composition, flow rates, and environmental variables. Designing heat exchangers with customizable features, control systems, and the ability to adapt to changing conditions is essential for ensuring operational flexibility.

- Safety Compliance: FLNG plants are subject to stringent safety regulations. Heat exchangers must incorporate safety precautions to prevent incidents such as leaks or over pressurization. This includes emergency shutdown mechanisms, temperature and pressure monitoring systems, and safety relief valves.

- Integration with Other Systems: Heat exchangers must seamlessly integrate with various interconnected systems within FLNG facilities, such as storage tanks, separators, and compressors. Collaborative design techniques and meticulous evaluation of the overall system structure are essential for efficient integration and optimal performance.

Waterman Engineers Australia's Expertise in Heat Exchanger Design for FLNG: Waterman Engineers Australia is at the forefront of engineering solutions, specializing in the design of heat exchangers tailored for FLNG applications. Their expertise has significantly contributed to optimizing FLNG plants while upholding the highest standards of excellence, sustainability, and safety.

- Cryogenic Expertise: Waterman Engineers Australia excels in addressing the challenges of cryogenic conditions in FLNG operations. Their team of experts possesses in-depth knowledge of designing heat exchangers capable of withstanding extremely low temperatures, a critical requirement for the liquefaction process. This expertise involves meticulous material selection, thermal management, and insulation techniques.

- Space-Efficient Designs: Recognizing the premium placed on space in FLNG operations, Waterman Engineers Australia employs creative and space-efficient design solutions. By leveraging advanced computational fluid dynamics (CFD) models and optimization methods, they strike a balance between effectiveness and compact size, ensuring that their heat exchangers meet space limitations without compromising performance.

- Safety Priority: Waterman Engineers Australia places safety at the forefront of their heat exchanger designs, fully understanding the stringent safety standards and regulations governing offshore activities. Their heat exchangers feature robust safety elements, including emergency shutdown mechanisms, temperature and pressure monitoring systems, and safety relief valves, to maintain integrity and compliance.

- Operational Flexibility: Waterman Engineers Australia's heat exchangers are designed with a keen awareness of the dynamic nature of FLNG operations. They provide the necessary flexibility to adapt to fluctuations in gas composition, flow rates, and environmental factors. Their choice of corrosion-resistant materials and proactive maintenance techniques further underscores their commitment to durability.

- Collaborative Integration: Waterman Engineers Australia employs a collaborative design approach that ensures seamless integration of their heat exchangers into the broader FLNG system. By actively participating in the overall FLNG system's design, they optimize the entire facility, ensuring that their heat exchangers complement and enhance the overall efficiency and performance of the FLNG facility.

Conclusion: Waterman Engineers Australia's heat exchangers for FLNG demonstrate a profound understanding of the complexities involved in offshore liquefaction processes. Their leadership in providing state-of-the-art heat exchanger solutions for the evolving FLNG operating landscape is driven by their expertise in cryogenic conditions, commitment to safety, space-efficient design solutions, and collaborative integration strategies.

Choose Waterman Engineers Australia's Heat Exchangers for Floating Liquefied Natural Gas (FLNG) to elevate your industrial processes to new heights. Contact them today to explore how their solutions can optimize your heat transfer applications and contribute to the success of your FLNG operations. With their expertise, you can navigate the challenges of FLNG operations with confidence and efficiency.

FAQs (Frequently Asked Questions) - Heat Exchanger Design for FLNG by Waterman Engineers Australia

Q1: What is the significance of heat exchangers in FLNG facilities?

A1: Heat exchangers are critical components in FLNG facilities as they are responsible for managing the heat transfer necessary to liquefy natural gas. They play a vital role in cooling the gas to extremely low temperatures, enabling its conversion into liquefied natural gas (LNG) for storage and transportation.

Q2: How do heat exchangers in FLNG handle cryogenic conditions?

A2: Heat exchangers in FLNG must withstand cryogenic temperatures, which is a major challenge. Waterman Engineers Australia addresses this by carefully selecting materials that can resist extreme cold, such as aluminum alloys and stainless steels. Additionally, insulation and thermal management techniques are applied to prevent heat loss and maintain the required low temperatures.

Q3: What design optimizations are employed to enhance the efficiency of heat exchangers in FLNG?

A3: To improve efficiency, modern heat exchanger topologies like spiral-wound or plate fin heat exchangers are used to provide a larger surface area for heat exchange in a compact design. Computational fluid dynamics (CFD) simulations are employed to optimize the design and arrangement of heat exchanger components.

Q4: How does Waterman Engineers Australia address space limitations in FLNG installations?

A4: Recognizing the limited space on FLNG platforms, Waterman Engineers Australia employs creative and space-efficient design solutions. They utilize advanced computational models and optimization methods to ensure that heat exchangers are both effective and compact, allowing them to fit within the space constraints without sacrificing performance.

Q5: What safety measures are incorporated into the design of heat exchangers for FLNG?

A5: Safety is a top priority in FLNG operations. Waterman Engineers Australia's heat exchangers are equipped with robust safety elements, including emergency shutdown mechanisms, temperature and pressure monitoring systems, and safety relief valves. These features are essential to prevent incidents like leaks or over pressurization.

Q6: How do Waterman Engineers Australia's heat exchangers adapt to the dynamic nature of FLNG operations?

A6: FLNG operations can experience variations in gas composition, flow rates, and environmental factors. Waterman Engineers Australia designs heat exchangers with customizable features, control systems, and the ability to adapt to changing conditions. This operational flexibility ensures optimal performance in the ever-changing offshore environment.

Q7: How does Waterman Engineers Australia ensure the longevity of their heat exchangers in harsh marine environments?

A7: Waterman Engineers Australia focuses on durability by using corrosion-resistant materials and coatings. Additionally, they implement strong maintenance and monitoring systems to detect and address potential corrosion issues, ensuring the extended life of their heat exchangers in challenging maritime conditions.

Q8: How does the collaborative integration approach benefit the performance of FLNG facilities?

A8: Waterman Engineers Australia actively participates in the design of the overall FLNG system, ensuring that their heat exchangers seamlessly integrate with other interconnected systems like storage tanks, separators, and compressors. This collaborative approach optimizes the entire facility, enhancing efficiency and performance.

Q9: Why should I choose Waterman Engineers Australia's heat exchangers for my FLNG operations?

A9: Waterman Engineers Australia's heat exchangers are designed with a deep understanding of the intricacies of FLNG operations. Their expertise in cryogenic conditions, commitment Designing OF SHELL AND TUBE Heat Exchangers for Floating Liquefied Natural Gas (FLNG) to safety, space-efficient designs, and collaborative integration strategies make them a reliable choice to optimize your heat transfer applications and contribute to the success of your FLNG operations.

Q10: How can I get in touch with Waterman Engineers Australia to discuss their heat exchanger solutions?

A10: You can contact Waterman Engineers Australia to explore their heat exchanger solutions and discuss your specific needs by visiting their website or reaching out to their dedicated team of professionals. They will be happy to assist you in enhancing the efficiency and safety of your FLNG operations.